This is a translation of my German blogpost Hinter den Beauty-Kulissen… ProTec Ingredia GmbH Proudly Presents: Vom Moos zum kosmetischen Wirkstoff. Enjoy!

In cooperation with ProTec Ingredia // „By the way, what happened to the moss we saw at Mibelle Biochemistry a few months ago?“ I ask Birgit Haemel from ProTec Ingredia. Birgit is excited: “We definitely need to visit the Mibelle lab in Buchs again; they’ve made some real progress with the ingredient”, she says. The algae farms of Brittany and Swiss-grown moss aren’t really that far apart, botanically speaking: mosses were the first organisms that made the evolutionary transition from sea to land. These tiny green plants are incredibly resilient and adaptable – they kickstarted evolution and changed the world.

Biotechnological innovation

We’ve returned to Switzerland and it is such a pleasure to see chemist Bernhard Henes again; I already introduced him two chapters ago. Bernhard and his team are responsible for the development of new raw ingredients and biotechnological processes at Mibelle Biochemistry. During my previous visit to the Mibelle lab I was surprised to learn that using moss as a cosmetic ingredient is difficult. It starts with the raw material: wild harvesting moss plants – i.e. picking them in their natural habitat – is really unsustainable whilst cultivating moss isn’t ideal either because the quality of the plant material is so uneven. However, mosses offer such interesting biochemical properties that Mibelle Biochemistry’s research team decided on a completely new approach.

In cooperation with Professor Dr. Reski from the University of Freiburg, the company developed an innovative biotechnological manufacturing process which is based on one of the most fascinating qualities of the moss plant. If a moss plant is injured by an external influence (for example, by a cut or tear), the affected plant cell immediately transmits this information. And now something extraordinary happens: young cell tissue (which is called protonema) starts growing from the injured leaf cell. Basically, the injury in the leaf doesn‘t merely repair itself (like you might expect) but it actually generates a new plant. Imagine if human bodies functioned like moss does: if you cut your arm by accident the skin wouldn’t just heal itself but would grow an entirely new human embryo. Did I mention that mosses are real survivors?!

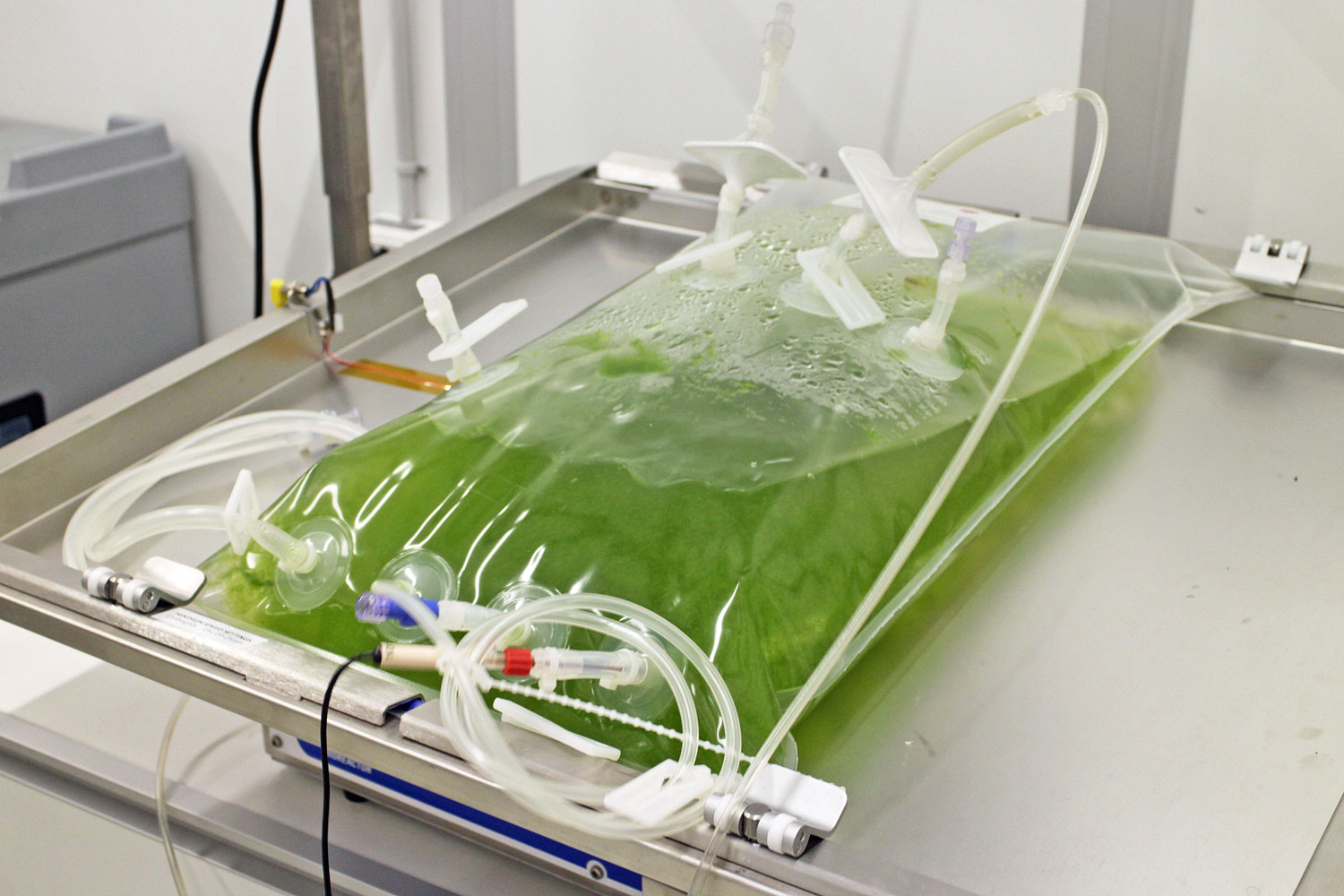

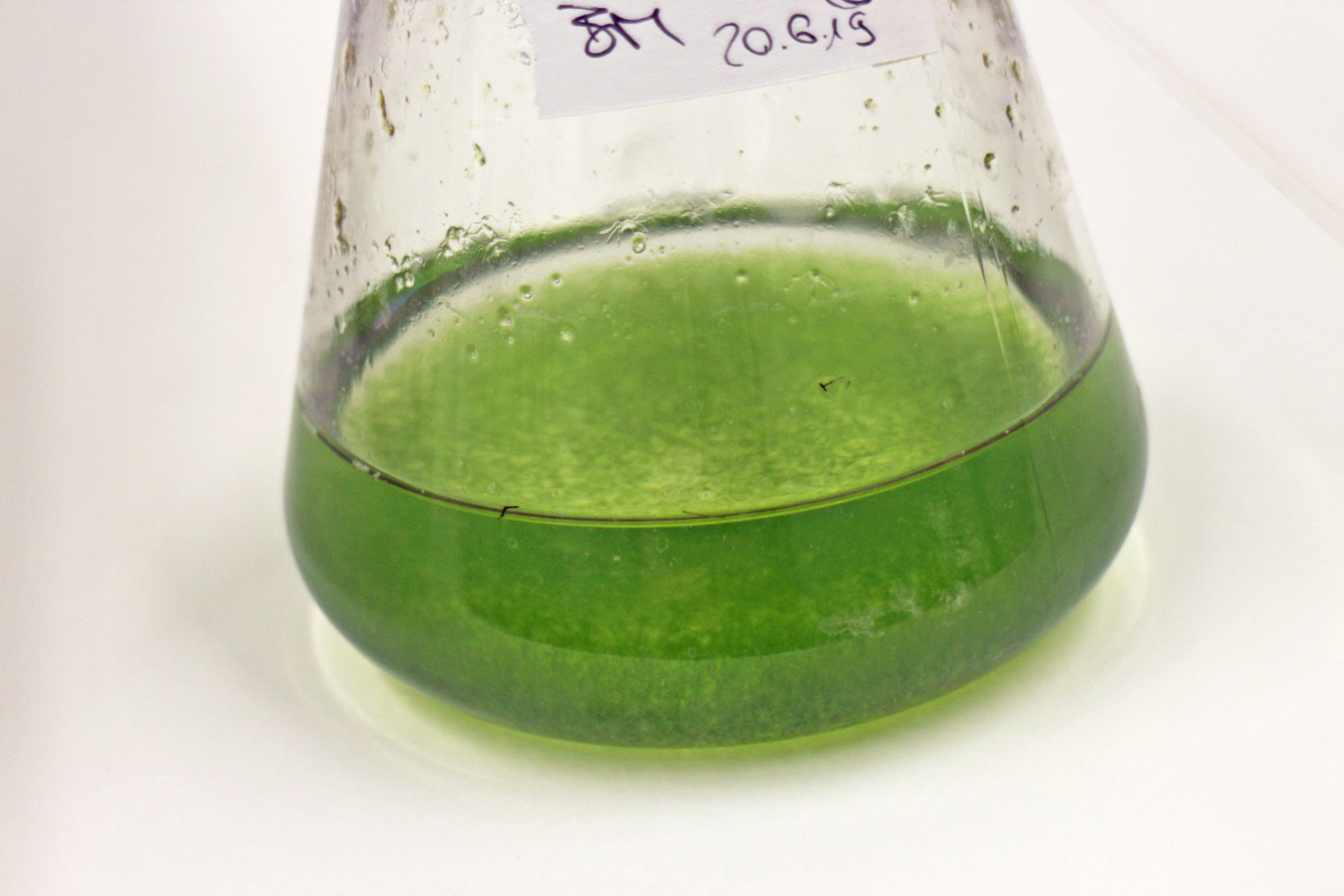

Mibelle Biochemistry decided to replicate this process in a phyto reactor. This is an enclosed container which is filled with a liquid plant culture – it’s similar to the set-up in micro algae cultures. In the picture above you can see a small version of the containers that are used in Mibelle‘s lab. The protonema suspension is mixed thoroughly at regular intervalls which stimulates the growth of new plant cells. After a period of 3-4 weeks the culture is enriched with many new protonema cells.

However, in order for the young cell tissue to flourish you need an optimal growth environment. There are many vital parameters: the composition of the nutrient solution and the nitrogen content are just as important as the level of illumination and the regular motion of the container. The rhythmical movement of the suspension ensures that all moss cells get enough light so they can multiply.

This is just the first step on the road to a new cosmetic ingredient. With its novel biotechnological manufacturing process Mibelle Biochemistry has managed to develop a sustainable way to generate enough young moss tissue. However, the green liquid isn’t a finished cosmetic ingredient yet; it has to be further developed before the moss extract can be used in an actual beauty product. So Bernhard and his team had to come up with even more innovative technological solutions.

From moss to the cosmetic ingredient MossCellTec™ No. 1

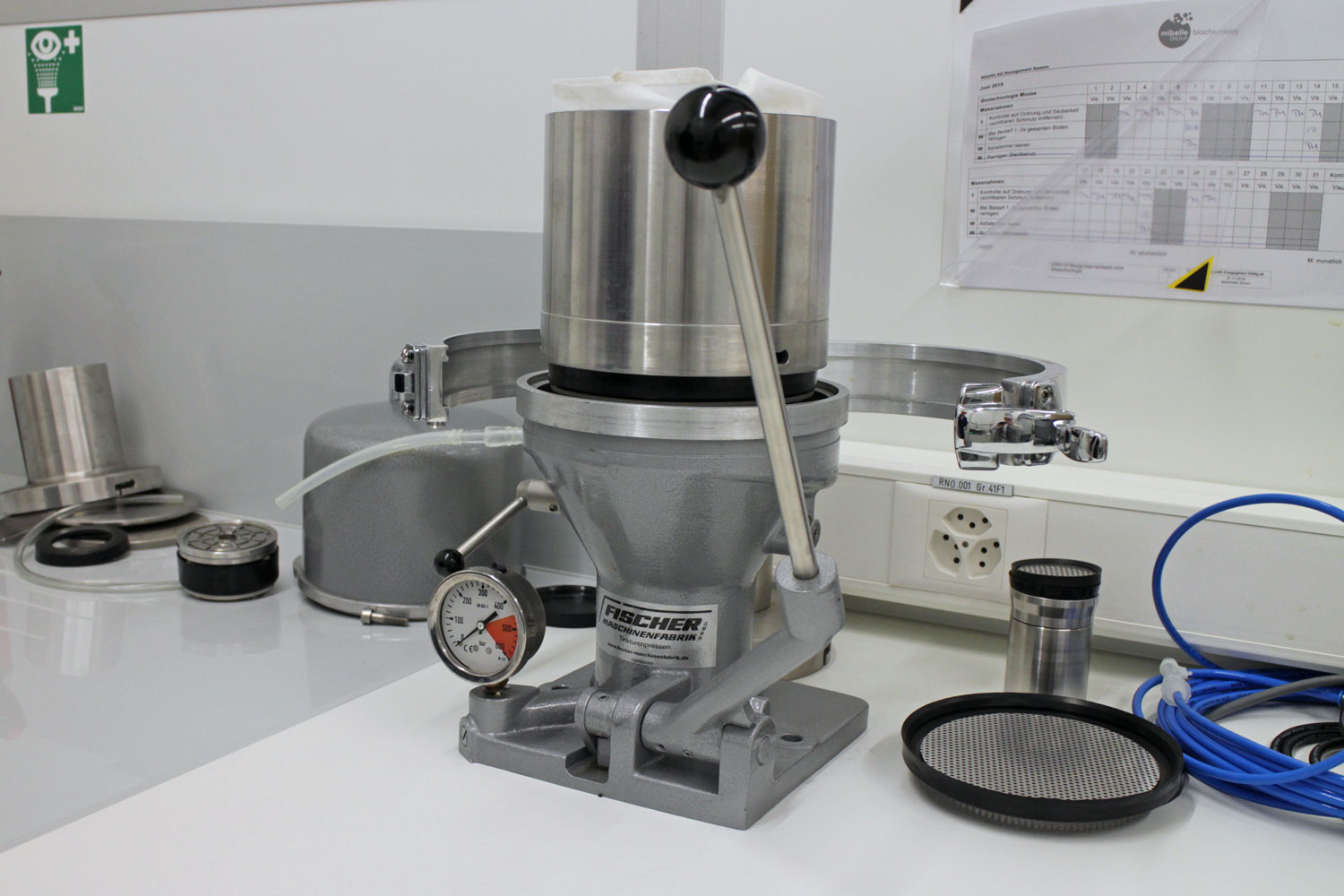

First the liquid moss culture is filtered through a sieve which separates the liquid from the bio mass. Then comes the next step: the extraction of the moss. Classic alcohol extraction didn’t yield satisfactory results; too many of the valuable secondary plant ingredients were lost in the process. It took Mibelle Biochemistry over six months to develop a gentler extraction process. Using a special cold pressing method the pure protonema is extracted under high pressure which helps to protect the high concentration of active ingredients in the moss.

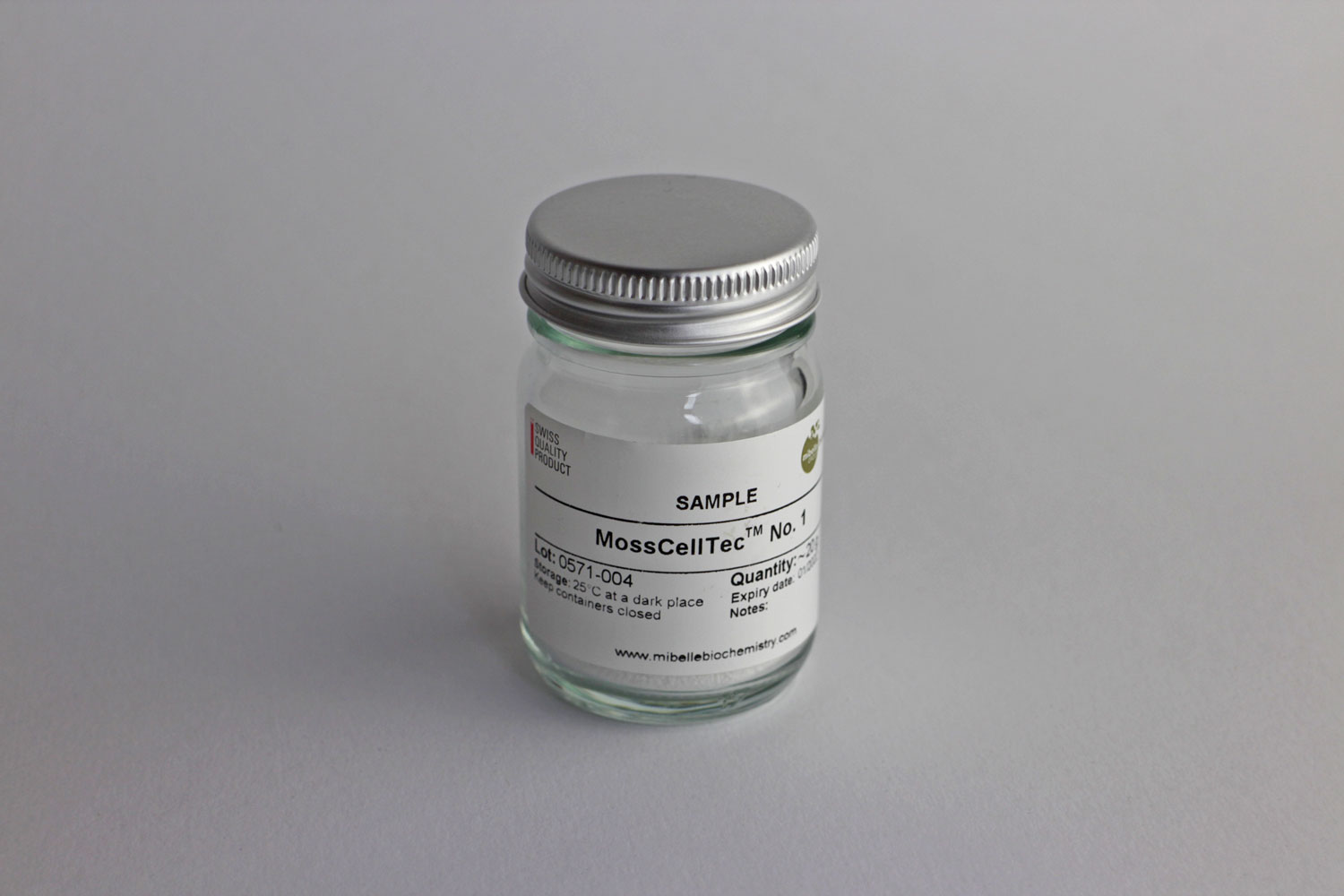

The resulting liquid extract is then spray granulated (it‘s sprayed on maltodextrin powder) and voilà: we have a pure active ingredient in powder form! Because this is a granulate (i.e. a dry powder) the ingredient doesn’t require any preservatives. It is also easy to use – cosmetics manufacturers can simply dissolve the moss extract powder in water – and was certified organic according to the Cosmos standard.

What Mibelle Biochemistry‘s MossCellTec™ No.1 does

The ingredient’s name MossCellTec™ No. 1 already indicates the active component and how it was manufactured. However, the biotechnological manufacturing process isn’t the only ingenious thing about this ingredient: the effects of MossCellTec™ No. 1 on the skin are equally innovative.

Studies have shown that the moss extract improves the health of the cell nuclei in ageing skin cells. By sustaining the structure and activity of the cell kernels in mature skin, MossCellTec™ No. 1 offers an entirely new anti-ageing approach. The extract also boosts the skin’s barrier function and increases hydration. In addition, clinical studies have proven that the skin adapts more easily to climatic changes because the vitality of the cell nuclei is improved. Basically MossCellTec™ No. 1 strengthens the resilience of the human skin – and here we come full circle, back to the resilient and adaptable moss plant.

I learned a lot during my visits to the Mibelle laboratory. Developing a new and innovative cosmetic ingredient can be pretty time-consuming and complicated. Some plants – such as moss – are difficult to source sustainably so you have to develop new processes which requires years of work and research and a lot of scientific know-how. And when you finally have your sustainably produced moss tissue the ingredient development process is still only half finished. You also need to develop a suitable and effective extraction method to safeguard the high concentration of active ingredients in the finished extract. And of course there‘s a further crucial step: researching and proving the effects of the new ingredient in clinical studies. I look forward to learning more about this in the near future (stay tuned!).

In the next chapter of Behind the Beauty Scenes I’ll be finding out how raw ingredients manufacturer Codif comes up with inspiration for new ingredients. Spoiler alert: sometimes the best ideas are generated at lunch time 🙂 .