This is a translation of my German blogpost Hinter den Beauty-Kulissen… ProTec Ingredia GmbH Proudly Presents: Im Labor mit McCell. Enjoy!

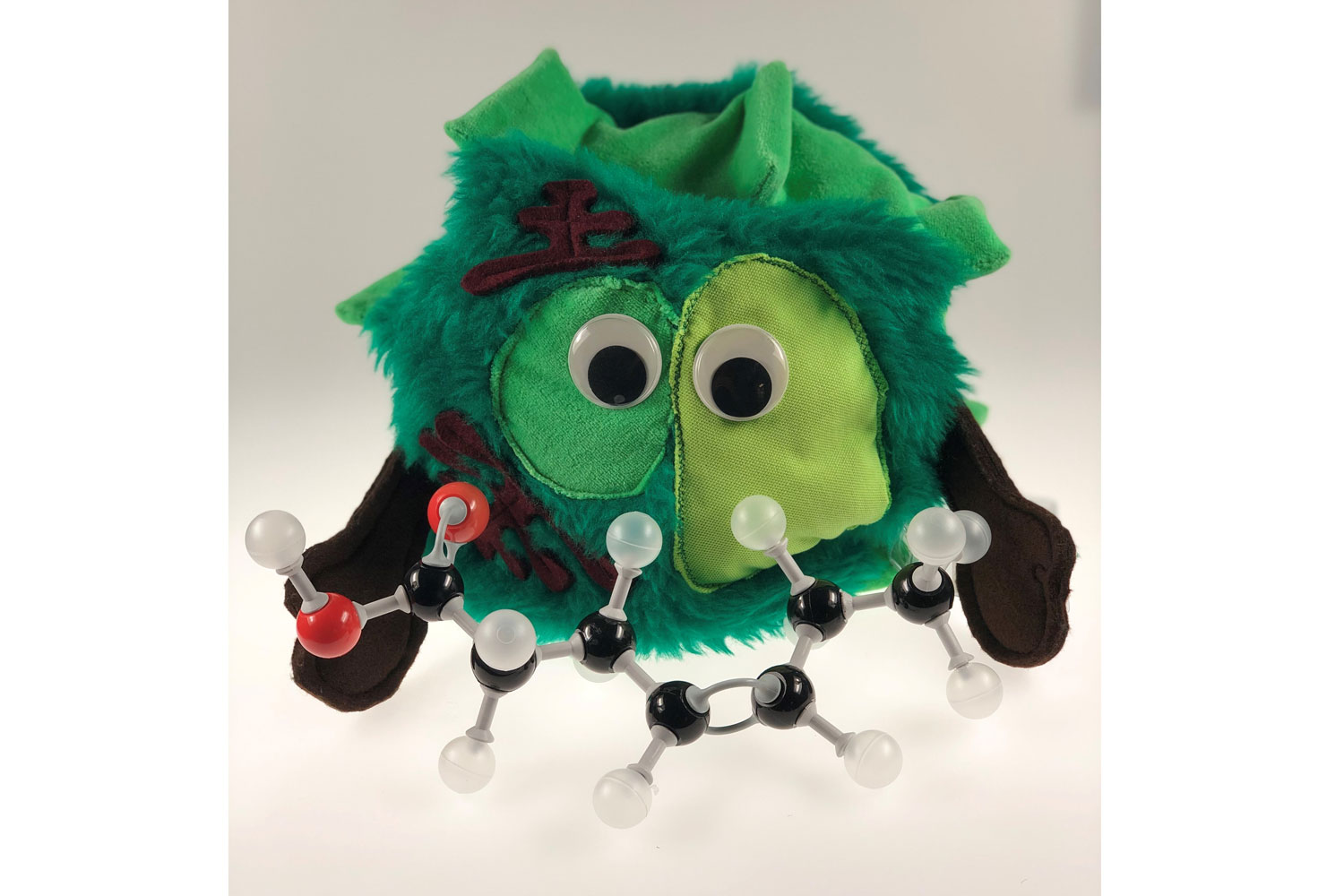

In cooperation with ProTec Ingredia // May I present? In this new chapter of my beauty serial story, we’re meeting McCell from the laboratory of Swiss cosmetic ingredients manufacturer Mibelle Biochemistry. McCell has been Mibelle’s mascot since 2019. His looks were inspired by a plant stem cell and he is aptly named: Mibelle’s best-known cosmetic actives are manufactured from plant cells.

McCell is also a true company creation: Mibelle lab technician Riika Sacher had an idea what McCell might look like and one weekend she sewed a prototype – can you see how his eyes look like the cell kernel and the cell’s vacuole?

McCell loves hanging out in the laboratory and enjoys passing on his knowledge (check out the Mibelle Biochemistry homepage for his article series “Learning with McCell“). I already learned quite a bit from him. It is also fascinating to get new insights into what a cosmetic ingredients lab looks like. So, put on a lab coat and some protective goggles and let’s join McCell!

McCell explains filtration

Filtering something – this sounds pretty easy, doesn’t it? But is it really? McCell explains that filtration helps to separate solids (undissolved particles) from liquids. It’s a bit like preparing tea or coffee: When you pour the hot water onto the coffee grounds or tea leaves the sieve (or filter) strains out the leaves/grounds. The smaller the pores of the filter or sieve are, the easier it is to filter insoluble particles from the liquid.

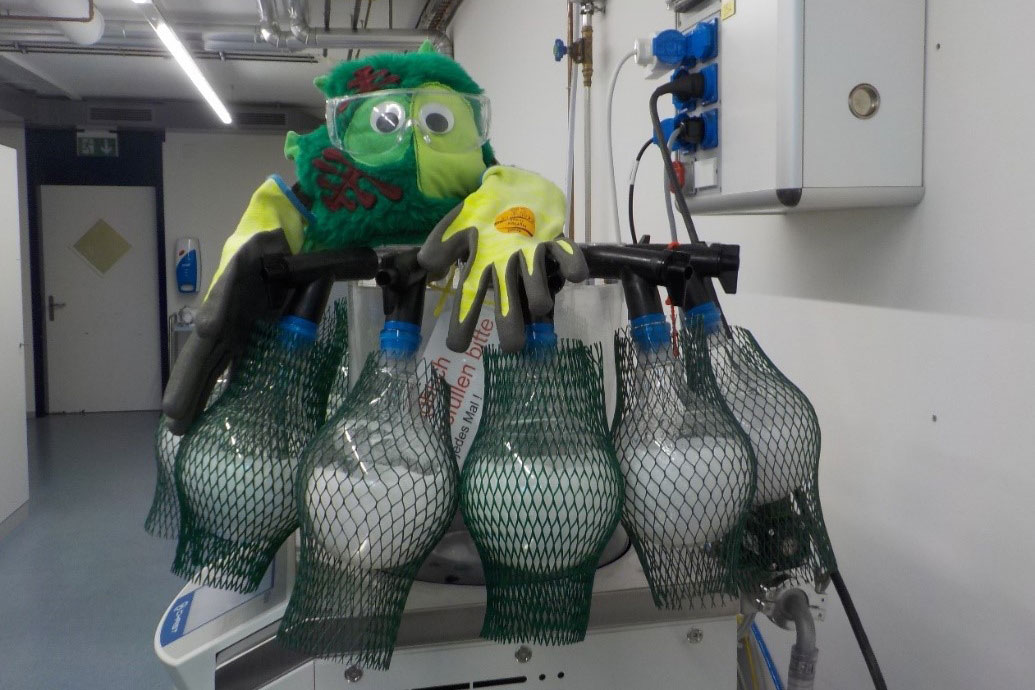

Filtering technology in a lab works the same way, using filters to separate solid substances from liquids. These filters are made from various materials and have very different pore sizes. Particles that are larger than the filter pores are strained out. McCell explains that you can also use pressure to accelerate the filtering process as you can see in the picture above.

Mibelle’s hair cosmetic active AnaGain™, for example, is manufactured from pea sprouts. After the extraction of the active ingredient, the remains of these sprouts are strained out with the help of a sieve. Afterwards, a 0,6-µm paper filter is used to filter all particles that are larger than 0,6 µm from the liquid. Since bacteria are bigger than 0,6 µm the resulting extract will be germ-free. As you can see, filtering can make a cosmetic ingredient more stable and therefore more durable (i.e. give it a longer shelf-life).

McCell explains lyophilisation

Have you heard of lyophilisation? This term refers to freeze-drying as McCell explains. You might be familiar with this process from your daily life, for example when drying your laundry in icy temperatures. Lyophilisation works because water turns from a solid to a gaseous state without liquefying once the surrounding temperature falls below a certain sub-zero temperature. This is also called sublimation. You might also recognise freeze-drying from certain foods: The berries in your morning muesli are usually freeze-dried because this process preserves the berry flavour very effectively.

Mibelle Biochemistry also uses lyophilisation when manufacturing peptides, by removing water from the frozen liquid that contains the raw ingredients. McCell shows what this laboratory process looks like: First, the watery peptide solution is frozen in an alcohol bath at -40°C until an ice layer with an approximate thickness of 1-2 cm has formed. Once the solution is frozen the gaps between the peptide molecules are fixed, they can’t be changed anymore. This way, the molecule structure becomes even and stable. The next step is to connect the frozen solution to the lyophilisation device and use a pump to create a vacuum. Now the water turns gaseous immediately leaving behind the peptides with their stable molecular structure. Of course, you need to wear protective gloves and goggles before starting with this process as you can see from McCell in the picture above.

McCell explains the saponification number

Once you start to more intensively research the world of oils and fats you will sooner or later come across the term „saponification number“. But what does this mean exactly and does saponification have anything to do with soaps? Luckily McCell can help us out! First, he explains how soaps are manufactured: For a classic soap, the oils and lye solution are blended and then everything is boiled up. During this so-called „saponification“ process the oil and lye mixture will generate glycerin (from the original oils) and fatty acid salts (which are actually the detergent substances in soap). Every oil acts differently during this process because of its specific fatty acid structure: The molecular structure of each fatty acid has different properties. In order to characterise each oil as precisely as possible certain values are measured, including the saponification number, explains McCell.

The saponification number indicates how much potassium hydroxide (lye) is necessary to saponify 1 gr of fat. With this number you can calculate how many fatty acids are contained in a certain oil – the higher the saponification number of an oil is, the more fatty acids it contains. This way you can identify oils or prove the purity of a specific oil. During his laboratory training, McCell has often determined the specific identity of oils and fats.

Of course, there are more parameters that help to characterise oils and fats. If you want to learn more from McCell, check out his series on the homepage of Mibelle Biochemistry. I think it’s a pity that we didn’t have a McCell when I was studying chemistry in high school – I would have had so much more fun learning things!

© Pictures: The pictures were supplied by Mibelle Biochemistry for the purposes of this blog post.

Corporate customers in Germany can purchase the cosmetic actives from Mibelle Biochemistry through its German distributor ProTec Ingredia.

In the next chapter of my beauty serial, we’ll be attending a webinar that will focus on oat and the topic of resilience. Stay tuned!