This is a translation of my German blogpost Hinter den Beauty-Kulissen… ProTec Ingredia GmbH Proudly Presents: Wie kosmetische Wirkstoffe bei Mibelle Biochemistry produziert werden. Enjoy!

In cooperation with ProTec Ingredia // Over the last year, we have learned a lot about scientific research and the various aspects associated with the sustainable production of cosmetic ingredients. In this chapter of my beauty serial, however, things will be much more hands-on! Join me as we put on lab coats and protective hoods and go off exploring the production facility of Mibelle Biochemistry in Switzerland.

Biotechnologist Peter Blum – head of production at Mibelle Biochemistry – tells me that the manufacturing process of cosmetic actives is a real logistical achievement. In an average workday Peter constantly oscillates between his office and the production halls. Based on the customer orders he prepares the weekly production schedule. And now let’s start our tour!

The production

Different ingredients have very different production requirements so everything begins with a detailed plan. First Mibelle Biochemistry’s research and production departments decide on which manufacturing method might be the most suitable for the proposed ingredient. The next step is to do a small test run in the lab and once the final manufacturing process has been locked into place, the real production begins.

Depending on which ingredient is being produced the plant material is blended, homogenised, or filtered. Since Mibelle Biochemistry offers a very wide range of raw ingredients, the production infrastructure is flexible and can easily be scaled up or down: the boilers and drums can hold amounts from 20kg to 200kg. In order to achieve the most high-quality ingredients, Mibelle Biochemistry uses different methods to further concentrate the active substances.

Pinolumin™ from Mibelle Biochemistry

„Oh, this smells wonderful!“ All of a sudden I feel like I’m walking in a forest – there’s such a lovely fragrance of stone pine in the air. We are standing in front of a dryer processing the active ingredient Pinolumin™ which is manufactured from Swiss stone pine (Pinus Cembra) wood chips. This highly-concentrated wood extract contains anti-inflammatory Pinosylvin which makes Pinolumin™ especially suitable for sensitive skin. The compound reduces skin redness and soothes irritation and inflammation.

Peter tells me that it wasn’t easy developing this ingredient. Mibelle Biochemistry‘s team spent a lot of time coming up with a suitable extraction method. Finally, it was decided to use a more elaborate manufacturing method in order to achieve the highest possible concentration of active compounds. Pinolumin™ is available as a liquid extract or in powder form. For the powder format, the active ingredient is sprayed onto a granulate such as maltodextrin which will easily dissolve in a cosmetic formulation.

CM-Glucan

Which is Peter’s favourite active ingredient? „CM-Glucan has an excellent effect and equally impressive research data. It’s a natural polysaccharide derived from baker’s yeast which stimulates immune reactions, soothing the skin and helping it to quickly regenerate itself „, he explains. With CM-Glucan Forte the skin’s immune system can be rebalanced which makes this ingredient interesting in the context of the current „Safe Beauty“ trend – cosmetics that strengthen the immune system and give the consumers a feeling of safety and trust when they use the products. (You can read more about the SARS-CoV2 activity in the skin and the immune-boosting properties of CM-Glucan Forte here).

Mibelle Biochemistry was the first company to develop a method to extract beta glucan from the cell walls of the yeast. Manufacturing beta glucan is a complex process: it takes around two weeks, with an additional two weeks for the extraction. Mibelle’s team also invested a lot of research into finding a way to ensure the water solubility of the compound – an important aspect if you want to use the ingredient in cosmetic formulations.

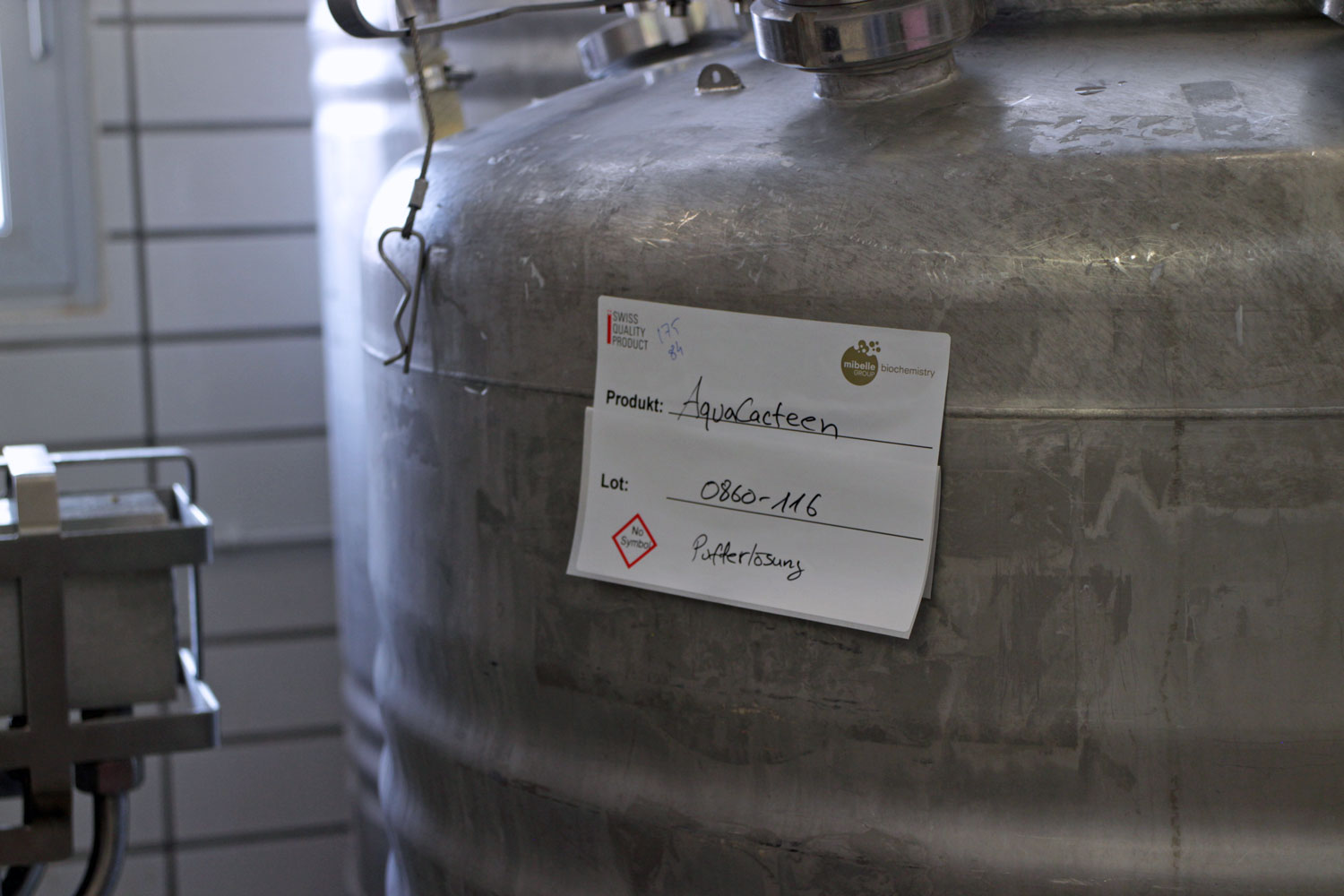

AquaCacteen™

In the next room we are walking past an extractor filled with prickly pear: Mibelle Biochemistry’s active ingredient AquaCacteen™ is based on the cactus fruit Opuntia Ficus Indica. In the extractor, the prickly pear plant material is extracted with a blend of glycerine and water. AquaCacteen™ reduces the release of stress markers from sensory nerve cells in the skin so it soothes the skin. The ingredient also has excellent hydrating properties thanks to the high percentage of water-binding compounds.

Mibelle Biochemistry’s laboratory carries out regular analyses such as chromatography and mass spectrometry throughout the entire production process of an ingredient, constantly monitoring the composition of the active ingredients.

Encapsulation technologies

Besides a high concentration of active compounds, the effectiveness of an ingredient also depends on how it is „packaged“ so the active substances can be transported into the skin. An unstable ingredient such as peptides can be encapsulated into liposomes which ensures that the ingredient remains active (and effective) for longer. Encapsulation technologies are highly complex and production processes often take place under very high pressure.

Packaging

When the active ingredients have been manufactured and undergone a final round of lab tests it’s time to get them bottled and packaged. The bottling of cosmetic actives takes longer than you might think: many powdery or liquid ingredients are decanted into the containers by hand. The standard size for canisters and tins is around 10kg. However, Mibelle Biochemistry also offers smaller and larger pack sizes for its cosmetic ingredients.

Dispatch

And now we’re in the dispatch centre. This is where the customer shipments are assembled: the cosmetic actives are very carefully packaged because they need to arrive at their destination in perfect condition. After a final check, the cosmetic ingredients are leaving on their journey – and will eventually reappear in the finished beauty products.

In the next installment of my beauty serial I will be talking to an industry insider who is responsible for awarding a renowned innovation price. Stay tuned!